Illini Hyperloop team competes at SpaceX, preparing for next year

Photo Courtesy of Richard Wendel

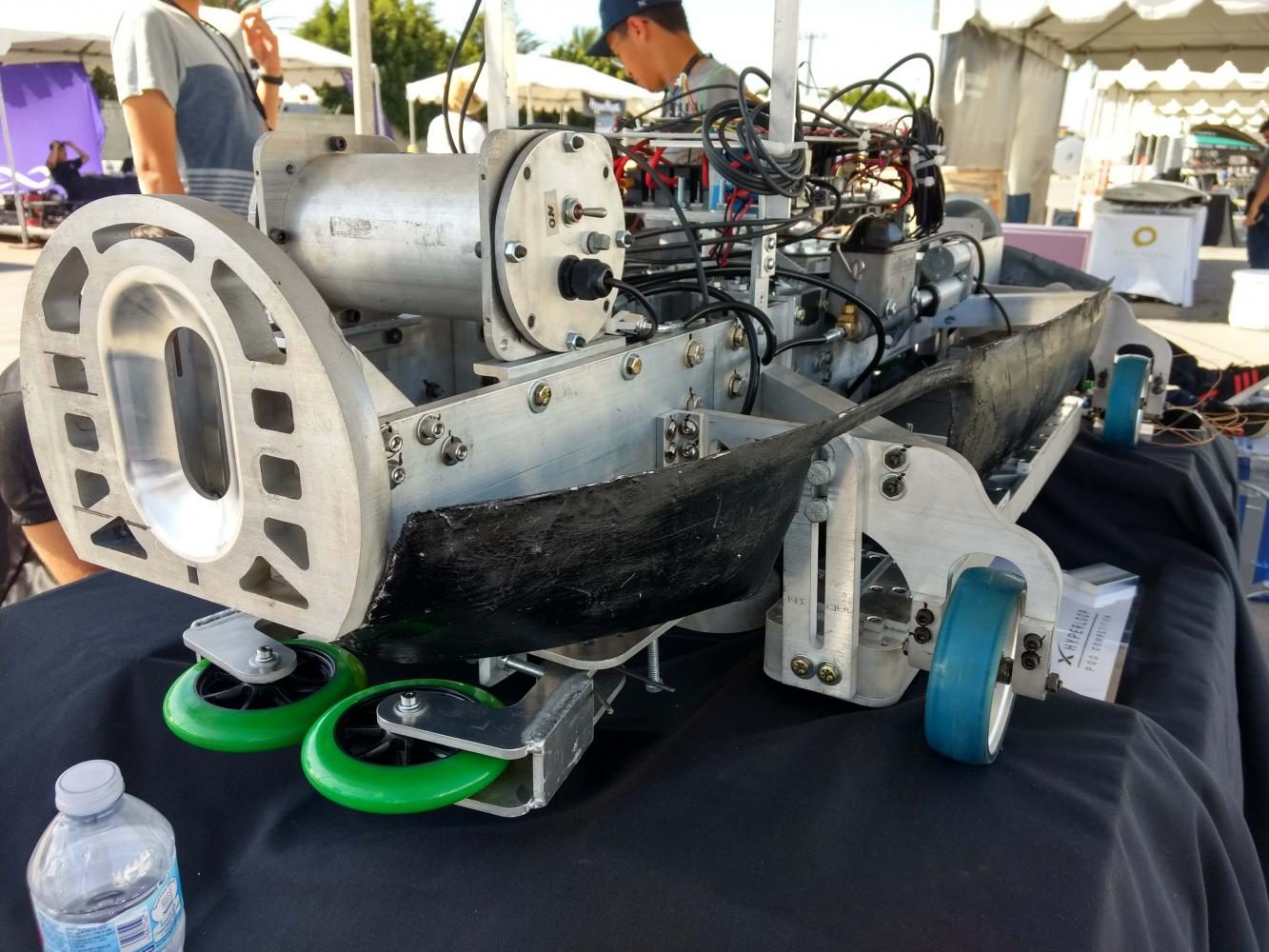

After competing at the second SpaceX competition in August, Illini Hyperloop is preparing their new pod for the upcoming year. The team spends time year round working on the designs and mechanical components.

Sep 5, 2017

The Illini Hyperloop team competed in the second SpaceX competition in Hawthorne, California from Aug. 25-27 showcasing their newly re-designed hyperloop.

A hyperloop is a pod that travels through a depressurized tube and is designed to significantly shorten travel time. The team made it through the first SpaceX competition last January and spent much of their time since then redesigning their original pod.

“It was a complete redesign of the entire pod,” said Richard Wendel, president of Illini Hyperloop and junior in Engineering. “We took some components from pod one. We used the same wheels, but how we incorporated (it) all together changed.”

27 teams were invited to the second SpaceX competition out of the original 150. The final three were the only ones selected to actually put their hyperloop in the “vacuum” which was a depressurized tube. To be one of the final three, the hyperloop must complete a number of safety tests.

“We ran into a mechanical issue with our brakes that prevented us from going very far,” Wendln said. “We tried to fix it, did our best, but unfortunately we could not make it too far into the competition.”

Get The Daily Illini in your inbox!

The team began designing the second hyperloop last February, but did not begin manufacturing until June.

“It was very stressful and it’s a good thing,” said Dohun Jeong, electrical lead and sophomore in Engineering. “There’s supposed to be a lot of blood and tears. The last month before the competition everyone was working an 80-90 hour work week.”

The cost of building a hyperloop able to compete is not low, however.

“The exact cost of the total project is not disclosed to students, even us,” Jeong said. “The original estimate was $25,000.”

Discounts were given to the team by Standard Electric Supply Company. Mechanical Lead and junior in Engineering, Brian Bailey, said that most of the funding came from the College of Engineering.

The 2018 SpaceX competition dates have not been announced yet, but the team is already thinking about improvements for their pod.

“We like the basic structure of our vehicle, now we want to automate a lot of systems,” Bailey said. “We want to actually be able to move our magnets. We’re going to fix our breaks, we’re going to get some good data.”

Part of what the team is able to do relies on its finances.

“A lot of what we do depends on budget, but luckily this time we don’t have to redesign the whole pod,” Welden said. “This year’s platform is much better and it’ll allow us to focus on the design. It’s easy to design something, it’s hard to manufacture it.”