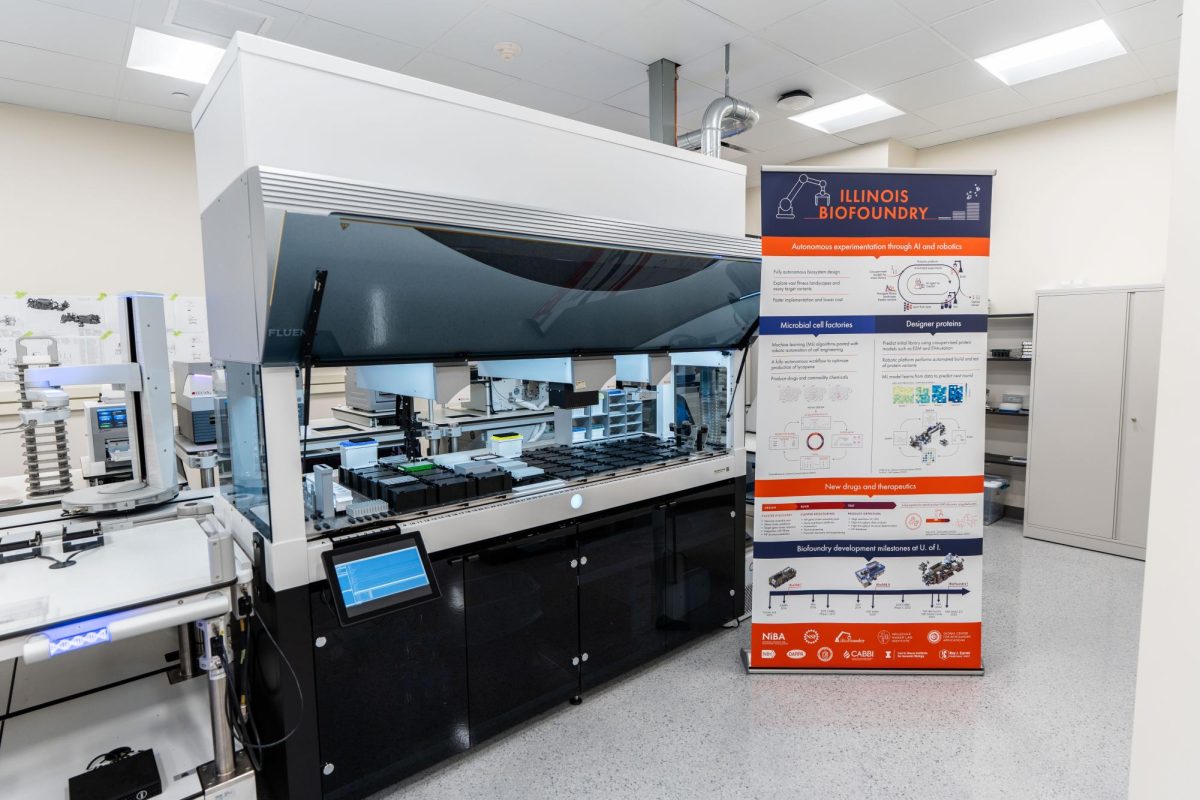

University researchers are harnessing artificial intelligence and robotics to accelerate biological discovery through the iBioFoundry — a facility designed to improve the way scientists design and test living systems.

The University celebrated the opening of the iBioFoundry with a ribbon-cutting ceremony on Sept. 18. The iBioFoundry, which is funded by the National Science Foundation, supports the nation’s growing focus on the bioeconomy, a growing field where renewable resources like plants and microorganisms are used to produce food, energy and industrial products.

A biofoundry is a facility designed to automate and engineer biological systems. This allows researchers to experiment with biological systems at a higher level.

According to Huimin Zhao, the director of the iBioFoundry and professor in LAS and Engineering, the first fully integrated biofoundry in the world was designed by the University in 2014, called the iBioFAB I.

The iBioFAB I is a fully integrated computational and physical infrastructure which allows for rapid design, fabrication, validation control and analysis of genetic constructs and organisms. The decade following the creation of the iBioFAB led to the creation of the iBioFAB 2.0 in 2020.

Get The Daily Illini in your inbox!

Zhao said that the new iBioFoundry is unique, as the biofoundry is driven by artificial intelligence and provides a way to quicken research in a current manner.

“We built this iBioFoundry to accelerate the design-build-test-learn cycle in synthetic biology,” Zhao said. “Biology has been used for many different applications, but these engineering and biological systems are very time-consuming.

The new iBioFoundry seeks to utilize AI to design and operate systems while using robotic systems to perform repetitive tasks that are required in the laboratory.

The design-build-test-learn cycle is central to synthetic biology and the iBioFoundry. With the use of AI and computational tools, scientists can design biological systems — such as biochemical pathways or whole microorganisms. Researchers can then build and evaluate the system and use machine tools to improve the design.

Zhao said that robotics can accelerate the process, making it more efficient.

Addie Potter, sophomore in LAS and Engineering, and research assistant working under Nilmani Singh, an automation engineer in the iBioFoundry, said the machinery allows for the work in her lab to be more efficient.

Potter works on machinery responsible for synthesizing proteins. She said because the iBioFoundry has a focus on autonomous experimentation, they use AI and machine learning to predict, synthesize and evaluate proteins.

“We do not have to synthesize all these proteins with different building blocks, as we can use AI to pinpoint what we want to build and see what happens with it,” Potter said.

The iBioFoundry seeks to address a crucial gap in biological engineering research. By accelerating the process of engineering microorganisms utilizing AI, the iBioFoundry can significantly reduce the amount of time spent on designing biological pathways.

This acceleration is beneficial for many fields of research, including bioeconomy research, said Jeremy Guest, professor in Engineering and director of the Levenick Center for a Climate-Smart Circular Bioeconomy.

“The bioeconomy uses plants and other natural resources to make food and everyday products that people need,” Guest said. “This includes crop production and sustainable forestry, the conversion of those renewable feedstocks into food, products and fuels, their distribution and sale to consumers and all of the enabling social systems, ecosystems and policies that make the system work for society.”

Illinois is quickly becoming the heart of America’s bioeconomy.

According to data from the TEConomy database, the state of Illinois ranks No. 2 nationally in producing direct industrial sector employment and leads the nation in bioeconomy output, contributing around $32 billion in total industrial bioeconomy revenue.

That momentum just gained a major boost with the opening of the iBioFoundry, as facilities like it drive the research that makes this progress possible.

“The University of Illinois Urbana-Champaign is a leading research institution across the full spectrum of topics supporting the bioeconomy, including in crop production, biomanufacturing, the marketplace and enabling social environmental systems,” Guest said. “The iBioFoundry represents a major advancement in national research capabilities in biomanufacturing — the use of microorganisms to convert one chemical to another.”

Guest added that the facility will have an influence far beyond the University.

“The iBioFoundry will help researchers here at the University and across the U.S to design and evaluate new biological pathways, speeding up innovation and the potential for societal impact,” Guest said.

Zhao said that the next step is to expand access to the iBioFoundry with the development of a cloud biofoundry, which could allow researchers to access the iBioFoundry remotely.

“We have developed quite a few applications already,” Zhao said. “For the future, in order to make the biofoundry broadly accessible, it is important to make it remotely accessible.”

In the future, this innovation could make the iBioFoundry available beyond campus, connecting scientists across the globe.