Researchers open earthquake center

Online Poster

Dec 2, 2004

Last updated on May 11, 2016 at 05:34 p.m.

On January 17, 1994, an earthquake wrecked the Santa Monica Expressway. Overpasses crumbled, columns were crushed and the deck pulled loose from its supports on the world’s busiest roadway, causing millions of dollars in damage.

Now, a team of University researchers has unveiled a new facility that they hope will help prevent future catastrophes and cement the University’s position at the forefront of earthquake research by studying why the bridge failed.

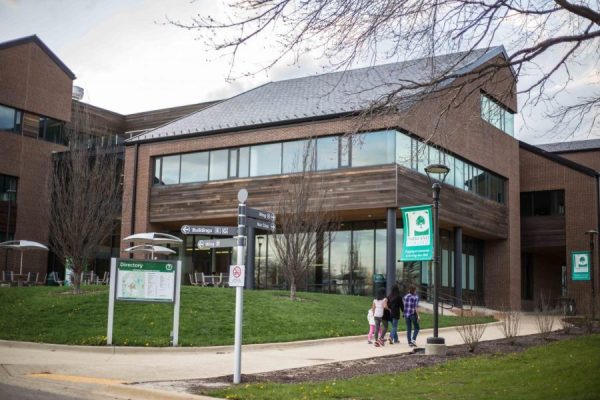

The Multi-Axial Full-Scale Sub-Structures Testing and Simulation (MUST-SIM) Facility is designed to test full-size models of structural components such as steel beams and concrete columns. It is part of a nationwide project to study the performance of buildings and bridges under earthquake conditions.

The University’s civil engineering department has been among the leaders in earthquake engineering since the late 1950s when Nathan Newmark was the head of the department, said Dan Kuchma, an assistant professor in civil and environmental engineering.

Get The Daily Illini in your inbox!

“We have an incredibly strong history in earthquake engineering,” Kuchma said. “For a long time, there wasn’t even a number-two university in this field.”

A gymnasium-sized room in Newmark Hall, named in the professor’s honor, houses the MUST-SIM facility.

Researchers celebrated MUST-SIM’s grand opening on November 15. Its first project is testing models of the bridge piers of the Santa Monica Expressway in an attempt to replicate the disaster and improve designs for the future.

The facility is one of 15 new experimental testing facilities across the United States. Each testing facility has equipment to test different pieces of a structure, while the rest are modeled by computers. As part of an effort headed by University professor Bill Spencer, data is shared between the sites so that researchers can test entire systems one piece at a time.

That, facility director Amr Elnashai said, is what makes the project unique.

“The actual columns of the Santa Monica Expressway were 50 feet apart,” Elnashai said. “You have a really complex system that could never be tested in one laboratory anywhere. So, instead, we spread the components out and make them think they are part of a complete system.”

MUST-SIM was funded by the National Science Foundation and is open for use by researchers throughout the United States. University professors designed and manage the facility.

“Anybody in the U.S. can write a proposal that goes to the National Science Foundation to conduct research in one of the facilities,” Kuchma said. “They select projects to fund each year that will run for the next three to five years.”

When MUST-SIM is used, a 35-ton loading box is attached to a “strong wall” over the pier to be tested. The boxes are capable of placing up to one million pounds of force on the pier in up to six different directions to simulate the full effect of an earthquake.

Videos of the MUST-SIM tests show large piers failing under the force of the machine. Concrete cracks and steel bars flex and snap as the pillar is cracked and sheared before finally giving way, sometimes explosively.

The facility’s uses extend beyond testing bridges. Because all the pieces are movable, Kuchma said, the same equipment could be used to test masonry walls, multi-story building frames and a variety of other structures.

Kuchma said the tests they have run on the piers have mirrored the actual damage caused by the earthquake. The next step is to apply changes to the components to improve their performance.

“We have a good facility to investigate failures and prevent them in the future,” Elnashai said. “We can create features that will behave better in future earthquakes.”