University researchers develop low-cost 3D-printed prosthetic hand

November 6, 2014

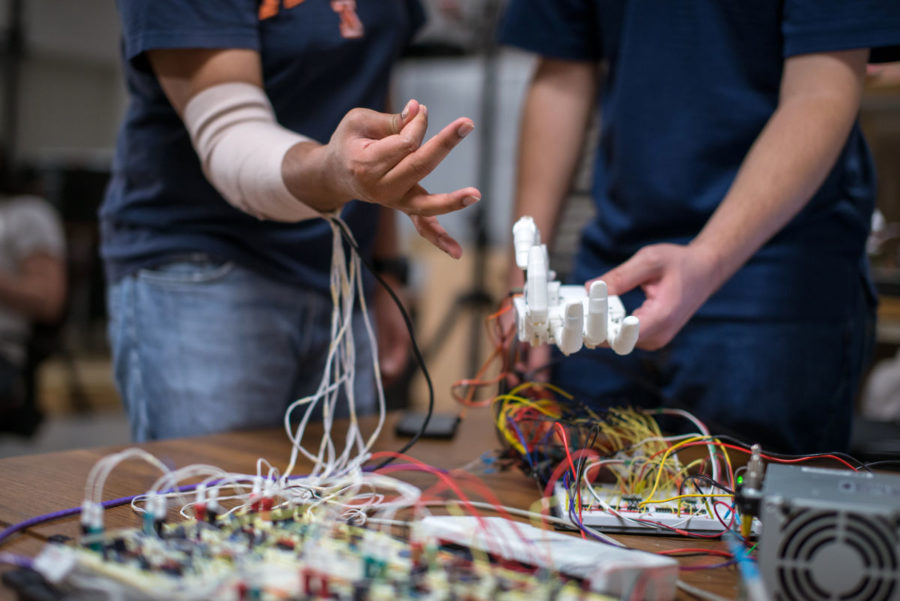

For amputees in developing countries the cost of prostheses can be too expensive, ranging in the tens of thousands of dollars. But a research team at the University may have found a solution to that problem with the development of a 3D-printed prosthetic hand with pattern recognition capabilities that can be made for $270.

Team members visited Ecuador in August to test their prototype, and hope to return as they continue their research.

Discovering the use of 3-D printing

The team, advised by Tim Bretl, associate professor in Aerospace Engineering, came together about three years ago to study ways to examine and control the use of prosthetics. The team is collaborating with the Rehabilitation Institute of Chicago.

Aadeel Akhtar, team leader and PhD student in Neuroscience, said the team is researching how to control prosthetic limbs by using muscle signals.

Get The Daily Illini in your inbox!

“The whole idea of using 3-D printer prosthetics came around about last year when I was talking to another group member, Mary Nguyen,” Akhtar said. “Around this time there was an explosion in using 3-D printer prosthetics; you would see a news article every day about the latest 3-D prosthetic hand.”

Patrick Slade, sophomore in Engineering, has been interested in the idea of prosthetics since high school, when he built the prosthetic hand using 3-D printing in his garage. When he arrived on campus as a freshman, he emailed Akhtar asking if the team had any use for the object. Since then, the team has been researching how to make prosthetic hands with a 3-D printer.

The current model

The team’s 3-D prosthetic hand can perform five positions that correspond to the user’s hand.

Akhtar said with a right muscle sensor, or electromyographic sensor, on the user’s forearm, the team employs machine learning algorithms.

“Using this machine learning algorithm, we have the user just train with performing the five different gestures that we can currently do: the hand at rest, the hand at opening, the hand closing, a three finger grasp and also a fine pinch,” Akhtar said.

Every week, each gesture is trained for two to three seconds, which will allow the machine learning algorithm to collect data and analyze the motions being made.

Development of the model

Akhtar said the team hopes to incorporate sensory feedback into the next version of the hand.

“No commercial device currently has any form of sensory feedback at all,” Akhtar said. “We want to be one of the first prosthetic hands out there that can incorporate this feedback into the device, also at a low price point.”

There are two types of sensory feedback that is given to prosthetic hand users. One type is proprioception sensory feedback, which is the ability to feel the position of a joint, Akhtar said.

“For instance, if an amputee were to close his eyes and move his prosthetic hand around, he has no idea what the joint positions are going to be like in that hand or what the shape of his hand is going to take,” Akhtar said. “If I close my eyes and move my hand around, I know exactly what shape my hand is making.”

One way the team is trying to give that sensation back to amputees is through a technique known as skin stretch. When the finger moves, Akhtar said, it proportionately stretches the skin so that the position of the joint angle being moved corresponds to the amount of skin stretch users feel.

Although the use of sensory feedback does not provide the same senses amputees had before their amputation, it tries to give them ways to feel through their prosthesis.

“After only six minutes of training, users were able to distinguish between six different grips, just based off the skin stretch,” Akhtar said. “They couldn’t see the device, they couldn’t hear the device at all and they were able to get above 88 percent accuracy in distinguishing the different grips that were being presented through skin stretch.”

The team is also working on a prototype that uses four-bar linkage, which Slade designed within about two weeks.

Slade said the four-bar linkage allows the joints to move in a natural, consistent manner because the joints are coupled together.

“The use of four-bar linkage – which is four mechanically bridged and rigid links that are all attached by joints – it will move through a small motion rather than the tendon winch method, where you are like pulling in the string,” Slade said.

Research in Ecuador

In collaboration with David Krupa, cofounder of Range of Motion Project and University alumnus, team members traveled to Ecuador to test their prototype.

“It was a very great experience working with an actual person who happens to have an amputation and who could help us with learning what we needed to do for our prosthetic device,” said Nguyen, graduate student in Aerospace Engineering. “It’s one thing to be up here testing the device; we do have some access, but when we are trying to develop devices for people in developing countries, it’s important to go down and see what the needs are and what they want.”

Nguyen said the experience with Juan Suquillo, an Ecuadorian patient who tested the device, was successful and fulfilling for everyone involved.

“The next time we go back, we plan on having a fully-functional prototype that we can actually leave for long-term testing,” Akhtar said. “Our goal in this first trip was just to make sure that we can actually get our devices to work.”

Akhtar said he and his team are trying to design a new prototype that would be able to completely fit into a socket and include all the electronic devises and the electromyographic sensor board. The team will continue working to make prostheses accessible to everyone who needs them.

Jane can be reached at [email protected].