University faculty creates 3D printer to aid in cancer research

September 20, 2018

Dr. Rohit Bhargava had a plan to design a 3D printing device capable of printing structures of microscopic sizes. And I was lucky enough to be able to hear why first-hand.

Contrary to any expectation I had, I certainly was not expecting a giddy monologue from a man in his 40s, brazen with vigor as he revealed the projects he’d finally brought to life after so many years of humbling work, instilling his excitement onto me regarding projects I had hardly yet understood.

Bhargava is the founder professor of engineering in the Department of Bioengineering and affiliate professor at Carle Illinois College of Medicine. He serves as the director of the Cancer Center at Illinois.

Bhargava’s vision was to create a device that could facilitate cancer research, and the final product has indeed proven his vision a success. This 3D printer has the ability to print structures of an amazing range of sizes, a crucial asset when dealing with microscopic cancer research.

The building of this printer required expertise across multiple fields due to its intricate qualities. Bhargava appointed Matthew Gelber, postdoctoral research associate in Bhargava’s group, to build this functioning 3D printer.

Get The Daily Illini in your inbox!

He then recruited Matthew Coler who dealt with programming the printer. Finally, he appointed Mark Reicha to perfect the imaging process, such that he could capture microscopic images.

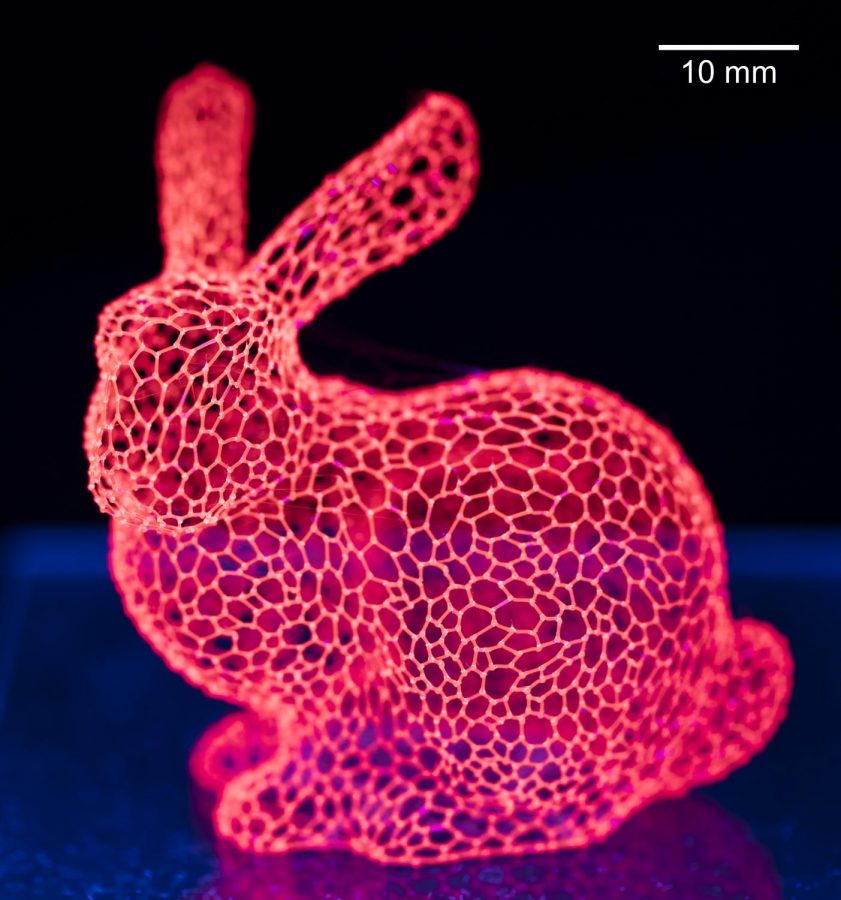

There are multiple properties to this device that makes it a particularly effective biomedical research tool. For one, this 3D printer can effectively create structural pieces, known as scaffolds, that can assist in the creation of certain objects that otherwise wouldn’t hold up. After the scaffold is created, the object is placed around the scaffold and then dissolved away, leaving the object structurally sound. It essentially allows for objects to be structured without gravity breaking them down.

Bhargava compares it to building an object using a mold.

“The concept behind the 3D printer is many years old, but hugely reimagined. We’ve had this technology for 2,000 years. It’s essentially creating a mold, which will be dissolved away, to create an object with a particular structure or shape, except now we can do it at a micron resolution with literally any shape you like,” Bhargava said.

Bhargava also analogizes scaffolds with something you wouldn’t expect: chocolate strawberries.

“If we made the shape of a strawberry, dip it into chocolate, then we have a chocolate-dipped strawberry, right? So imagine the strawberry is your scaffold. Now, if you could somehow eat away the strawberry, you’d be left with a chocolate mold in the shape of a strawberry,” Bhargava said.

Moreover, this printer employs the free-form printing technique, which allows for far greater maneuverability in the development of bio-scaffolds. The other type of 3D printing technique, the common commercial 3D printing, is layer-by-layer printing, but this would be ineffective when developing scaffolds for circular objects.

This is necessary because, as Bhargava said: “None of our biological features are rectangular. They’re all circular. You can’t print anything biological with a layer-by-layer commercial 3D printer.”

So with high precision, sugar free-form printing, they can create scaffolds around which they can structure objects, and then the sugar can be easily dissolved.

Furthermore, the printer can deal with objects of microscopic size; this is necessary when attempting to recreate conditions in the human body for detailed observation in the lab. Thus, in these structures, it’s necessary to design little lines, or filaments, to hold these structures together.

“It patterns little lines and little filaments of sugar in three-dimensions,” Gelber said.

In other words, it can create cross-sections, so it allows for the most approximate level of detail within these microscopic parameters.

Another unique aspect of this printer is its use of sugar alcohol isomalt, as opposed to regular sugar or plastics which are used by other 3D printers. Isomalt facilitates the free-form printing process in its versatility.

“There are other ways of doing free-form printing, anything that can move in three-dimensions simultaneously in principle could be used for free-form,” Gelber said. “But for patterning, some things work better than others. The key thing is that once the liquid comes out of the nozzle, it has to become stiff. Sugar is particularly good for that because of the way it flows, cools and then stops flowing.”

Another beneficial utility of isomalt is its minimization of error. It avoids problems that would normally arise using regular sugar. Whereas sugar burns and crystallizes, rendering it a far more problematic and burdensome process, isomalt dissolves, granting its users a lot more flexibility.

This printer has extraordinary biomedical research potential and may even possess the ability to bring significant light to cancer treatments in the future. Bhargava’s work will not end here.